|

|

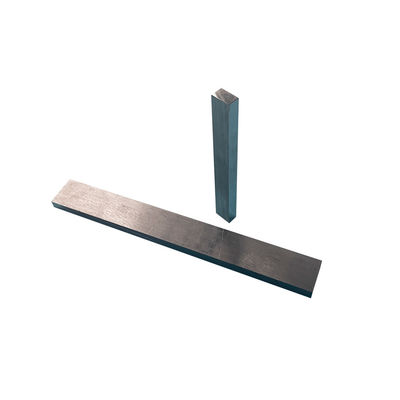

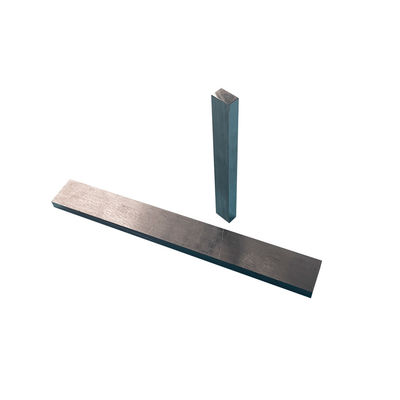

Placa Invar 4J36 de CTE quase zero (UNS K93600) Metrologia de precisão e aplicações criogénicas

|

|

Detalhes do produto:

Condições de Pagamento e Envio:

|

| Material: | 4J36 | Supply Type: | Plate |

|---|---|---|---|

| Color: | Primary Color | Surface: | Bright and Smooth |

| Destacar: | Chapa de Invar 4J36 para metrologia de precisão,Chapa de liga de baixa expansão com aplicações criogênicas,Chapa de Invar UNS K93600 para metrologia |

||

Placa Invar 4J36 de CTE quase zero (UNS K93600) Metrologia de precisão e aplicações criogénicas

OhmAlloy-4J36 (Invar), também conhecido genéricamente como FeNi36 (64FeNi nos EUA), é uma liga de níquel-ferro notável por seu coeficiente de expansão térmica excepcionalmente baixo (CTE ou α).

O nome Invar vem da palavra invariável, referindo-se à sua relativa falta de expansão ou contração com mudanças de temperatura.

Foi inventado em 1896 pelo físico suíço Charles Édouard Guillaume, que recebeu o Prêmio Nobel de Física em 1920 por sua descoberta, que permitiu melhorias nos instrumentos científicos.

OhmAlloy-4J36 (Invar) é utilizado onde é necessária uma elevada estabilidade dimensional, tais como instrumentos de precisão, relógios, medidores de fluxo sísmico, monturas de máscaras de sombras de televisão, válvulas em motores,e relógios antimagnéticosNo levantamento do solo, quando se pretende realizar um nivelamento de elevação de primeira ordem (alta precisão), o bastão de nivelamento (stafa de nivelamento) utilizado é feito de Invar, em vez de madeira, fibra de vidro ou outros metais.Os suportes Invar foram usados em alguns pistões para limitar sua expansão térmica dentro de seus cilindros.

Composição normal em %

| Não. | 35 a 37.0 | Fe | Balão. | Co | - | Sim | ≤ 0.3 |

| Mo. | - | Cu | - | Cr | - | - Não | 0.2~0.6 |

| C | ≤ 0.05 | P | ≤ 0.02 | S | ≤ 0.02 |

Propriedades físicas típicas

| Densidade (g/cm3) | 8.1 |

| Resistividade elétrica a 20°C(Ωmm2/m) | 0.78 |

| Fator de temperatura de resistividade20°C~ 200°C)X10-6/°C | 3.7~3.9 |

| Conductividade térmica, λ/W/(m*°C) | 11 |

| Ponto de Curie Tc°C | 230 |

| Modulo elástico, E/ Gpa | 144 |

Coeficiente de expansão

| θ/°C | α1/10-6°C- Um. | θ/°C | α1/10-6°C- Um. |

| 20 ~ 60 | 1.8 | 20 ~ 250 | 3.6 |

| 20 ~ 40 | 1.8 | 20 a 300 | 5.2 |

| 20 ~ 20 | 1.6 | 20 ~ 350 | 6.5 |

| 20 ~ 0 | 1.6 | 20 ~ 400 | 7.8 |

| 20 ~ 50 | 1.1 | 20 ~ 450 | 8.9 |

| 20~100 | 1.4 | 20 ~ 500 | 9.7 |

| 20 ~ 150 | 1.9 | 20~550 | 10.4 |

| 20~200 | 2.5 | 20 ~ 600 | 11.0 |

Propriedades mecânicas típicas

| Resistência à tração | Extensão |

| MPa | % |

| 641 | 14 |

| 689 | 9 |

| 731 | 8 |

Fator de resistência a temperatura

| Intervalo de temperatura, °C | 20 ~ 50 | 20~100 | 20~200 | 20 a 300 | 20 ~ 400 |

| a)R/ 103*°C | 1.8 | 1.7 | 1.4 | 1.2 | 1.0 |

Processo de tratamento térmico

| Processo de tratamento térmico | |

| Requeijão para aliviar o stress | Aquecido a 530~550°Ce mantenha 1 ~ 2 h. Frio para baixo |

| Requeijão | Para eliminar o endurecimento, que deve ser produzido em processo de laminagem a frio, o processo de desenho a frio.°C Em vácuo, espera 30 minutos. |

| O processo de estabilização |

1) Em meios de protecção e aquecidos a 830 °C°CEspera 20 minutos. - 1 hora, apague. 2) Devido ao esforço gerado pelo apagamento, aquecido a 315 °C°CAguarde 1 a 4 horas. |

| Precauções |

1) Não pode ser endurecido por tratamento térmico 2) O tratamento de superfície pode ser de areia, polir ou decapagem. 3) A liga pode ser utilizada em solução de decapagem de ácido clorídrico 25% a 70 °C.°Cpara limpar a superfície oxidada |

Qual a diferença entre Inconel e Invar 36?

A escolha entre os dois deve basear-se nos requisitos específicos da aplicação em particular.Por outro lado,O Conel é uma aplicação perfeita que requer alta resistência e resistência ao calor.

![]()

Pacote

![]()

![]()

Pessoa de Contato: Mr. Qiu

Telefone: +8613795230939

-

Ppm°C da liga de níquel 1,2 do ferro da expansão do Invar Fe-Ni36 4J36 anti corrosão do baixo

-

ligas da expansão da selagem de vidro de 4J29 Kovar FeNi29Co17 baixas

-

Vidro da tira das ligas 4J29 da expansão de Kovar baixo - - Metal o selo para ampolas

-

Banda de vedação de liga 42 FeNi42 para vedação de vidro cerâmico-metálico

-

Kovar 4J29 Rod de vedação de precisão polida para retorno hermético

-

Liga de precisão 42 FeNi42 Faixa de vedação de baixa expansão